Safe Payment

Pay with the world’s most payment methods.Confidence

Protection covers your purchase and personal data.Delivery

FREE & fast shipping all over the PakistanHotline

Talk to help line for your question herePhone & WhatsApp (+923000349558)

Product Details

VX101.00 Ultra Transparent Glossy Casting Epoxy + HX100 Hardener For Epoxy (Epoxy Complete Set)

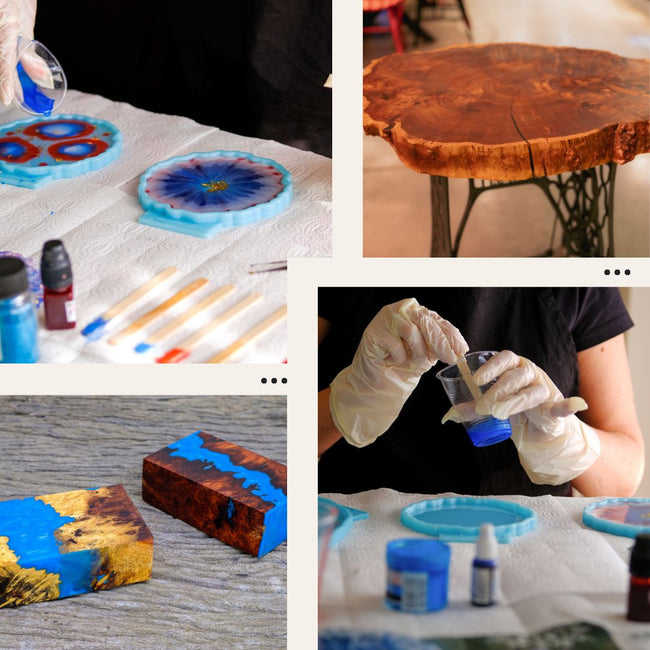

Discover excellence in woodworking with WoodEmotions' latest offering, the VX100.00 Transparent Epoxy Resin. This solvent-free modified Genc epoxy boasts exceptional bonding strength, chemical and physical high-resistance, and a remarkable ultra-transparent, low-density varnish. Let's dive into the details that make this high gloss epoxy resin a game-changer for woodworking enthusiasts.

Key Features

1. High Yellowing Resistance

Experience unparalleled longevity and clarity in your woodworking projects. The Genc epoxy resin high yellowing resistance ensures that your creations maintain their pristine appearance over Time, resisting discoloration or fading.

2. Long Mixing Time

Enjoy the convenience of an extended mixing time. This feature provides flexibility during the application process, allowing you ample Time to ensure thorough and precise mixing for optimal results.

3. Good Penetration and Minimum Foam Formation

Achieve professional-grade outcomes with the epoxy's excellent penetration into surfaces and minimal foam formation. This ensures a smooth and flawless finish, free from unwanted bubbles or inconsistencies.

4. High Thickness Application at One Time

Embrace efficiency in your woodworking endeavors. The epoxy allows for high-thickness application in a single coat, reducing the need for multiple layers. This saves time and ensures a robust and durable finish for various woodworking applications.

Recommended Uses

WoodEmotions introduces the versatile VX100.00 transparent epoxy resin, suitable for a variety of applications:

1. Casting in Wood Applications

This transparent epoxy is perfect for casting in diverse wood projects, delivering a seamless, polished finish that enhances overall visual appeal.

2. Three-Dimensional Applications

Craft three-dimensional art confidently with this epoxy, designed to bring intricate designs to life while ensuring clarity and durability.

3. Hobby Use

Whether you're a seasoned artisan or a hobbyist, this epoxy is user-friendly, catering to various creative projects with reliability.

4. Mold Creation and Impregnation

Tailored for mold creation, this epoxy coating facilitates precise mold development. Additionally, it excels in impregnation applications, ensuring an even and thorough coating.

Uses Of Transparent Epoxy Resin

- Ideal for creating stunning epoxy resin art pieces with clarity and durability.

- Perfect for crafting epoxy tables, ensuring a glossy and long-lasting finish.

- Suitable for epoxy flooring applications, providing a durable solution for interior floors.

Surface Preparation

To achieve optimal results with VX100.00 Ultra Transparent Glossy Casting Epoxy, thorough surface preparation is essential:

1. Removal of Surface Impurities

Before application, eliminate oil, grease, dust, dirt, rust, paint, oxides, corrosion products, or other impurities. This step is crucial for proper adhesion and a flawless finish.

2. Moisture Control

Thoroughly dry wood surfaces designated for casting, ensuring that the moisture content in the wood does not exceed 4%. Controlling moisture is vital to prevent unwanted reactions and maintain the epoxy's effectiveness.

Mixing Ratio

For the successful application of VX 100.00 epoxy transparent, follow the precise mixing ratios detailed below:

|

Description |

Code |

By Weight (%) |

By Volume (%) |

|

Ultra Transparent Glossy Casting |

VX 100.00 |

100 |

100 |

|

Epoxy Hardener |

HX100.00 |

33 |

38 |

Usage Instructions

Before usage, ensure a thorough mixing process:

1. Stir Well

Before applying, stir the epoxy and hardener mixture thoroughly. This step is crucial to achieve uniform consistency.

2. Check Homogeneity

Ensure Homogeneity in the mixture by visually inspecting its evenness. A well-mixed solution is essential for optimal performance.

Note:

- Adhering to the specified mixing ratios is critical for achieving the desired results.

- Exercise caution and precision during the mixing process to guarantee the effectiveness of VX100.00 epoxy resin casting in your woodworking projects.

Application Instructions

To ensure optimal results when applying VX 100.00 Genc epoxy, follow these straightforward guidelines:

1. Mix Until Homogeneous

Thoroughly mix the epoxy and hardener until achieving Homogeneity. A consistent mixture is essential for a uniform and professional finish.

2. Maintain Proper Mixing Ratio

Adhere to the specified mixing ratio to guarantee the epoxy's effectiveness. Precision in mixing contributes to the epoxy's performance and durability.

3. Application Conditions

Apply the epoxy under the following conditions:

- Ambient humidity should fall between 10% and 85%.

- Ensure an application temperature of a minimum of 10˚C.

- The applied surface will be ready for use at 20˚C after seven days.

4. Application Equipment

No special tools are required for the application. The casting process can be seamlessly executed without the need for specialized equipment.

Product Specification

|

Property |

Specification |

|

Product Type |

Epoxy |

|

Specific Gravity (kg/l) |

1.08 ± 0.03 |

|

Solid Content (% by weight) |

99-100 |

|

Theoretical Coverage Area |

1.00 - 1.10 m²/l |

|

Recommended Dry Film Thickness |

10000㎛ - 60000㎛ |

|

Application Thickness per Coat (multi-layer) |

Minimum 30000 ㎛ |

- VX 100.00 Genc epoxy falls under the Epoxy product type.

- The specific gravity is 08 ± 0.03, ensuring an optimal application density.

- The epoxy boasts a solid content ranging from 99% to 100%, ensuring a high concentration for robust performance.

- The theoretical coverage area is estimated to be between 00 and 1.10 square meters per liter, allowing for efficient usage.

- The recommended dry film thickness spans from 10000㎛ to 60000㎛, providing flexibility based on application method, seasonal conditions, and surface properties.

- In multi-layer applications, it is advised to maintain a minimum application thickness of 30000 ㎛ per coat for optimal results.

These specifications provide a comprehensive overview of the critical properties, allowing users to make informed decisions regarding applying VX100.00 Genc epoxy in their woodworking projects.

Drying Time

|

Drying Phase |

Time (23°C) |

Time (30°C) |

|

Touch Dry |

12 hr |

10 hr |

|

Full Dry |

24 hr |

18 hr |

|

Second Layer Application Drying (min.) |

2 days |

1.5 days |

|

Maximum Standby Time After Mixture Prep |

30 min |

20 min |

|

Pot Life |

10 hr |

8 hr |

- The touch-dry phase takes approximately 12 hours at 23°C and 10 hours at 30°C.

- Complete dryness is achieved in about 24 hours at 23°C and 18 hours at 30°C.

- For the second layer application, drying times are 2 days at 23°C and 5 days at 30°C.

- After preparing the mixture, the maximum standby time is 30 minutes at 23°C and 20 minutes at 30°C.

- The pot life of the mixture is 10 hours at 23°C and 8 hours at 30°C.

- Drying times may vary based on temperature, humidity, film thickness, color, and air movement.

Color and Gloss Option

|

Product |

Product Code |

|

Ultra Transparent Glossy Casting Epoxy |

VX 100.00 |

|

Color |

Color Code |

|

Transparent |

0000 |

Storage and Handling

- Store VX 100.00 Ultra Transparent Glossy Casting Epoxy in a cool, dry place, away from heat.

- Close all containers securely after each use to maintain product integrity.

- The shelf life is two years when stored under specified conditions.

Health and Safety

- For comprehensive Health and Safety information, please consult the Safety Data Sheet.

- Wear suitable protective equipment such as glasses, gloves, and a mask when using these products.

- Ensure good ventilation in the working environment to minimize exposure.

- Refrain from smoking during product use, and remove epoxy from devices that may cause heat, fire, or sparking.

Warning

- Adhere to all warnings and instructions on the product label before use.

- Exercise caution and follow the manufacturer's recommendations when using painting equipment.

- Low temperatures, poor air circulation, or high humidity may extend dry times and negatively impact product performance.

- Keep VX 100.00 Ultra Transparent Glossy Casting Epoxy out of reach of children.

Transport Information

- Freight Classification: Epoxy

- Packaging: 27 kg set and 3 kg set

Note: These guidelines ensure the safe and effective use of WoodEmotions' epoxy, providing essential information for storage, handling, and transportation.

Competitive Resin Epoxy Prices in Pakistan!

Discover competitive resin epoxy prices in Pakistan, ensuring top-notch quality for your projects. Find where to buy epoxy resin in Pakistan, exclusively through WoodEmotions, your trusted source for superior materials.

Elevate your creations with WoodEmotions' epoxy resin, designed to meet the unique demands of the Pakistani market. Discover quality and affordability with WoodEmotions as you explore the latest epoxy paint prices in Pakistan. Trust us for premium products tailored to your needs.

Product Reviews

Shipping & Returns

In case of any Query visit

https://woodemotions.pk/pages/contact